In the flex circuit board manufacturing process, care must be taken to ensure the board is flexible enough to fit inside a small camera or cell phone, for example, but strong enough not to break. As a result of their need to bend and twist at different, sometimes odd angles, flexible circuit boards have been nicknamed origami circuitry. The insulating material is cut to size and then sandwiched in between two layers of copper. All of this is done in an exceptionally clean environment with sophisticated air filtration systems. Anyone working in the environment is wearing a full protective suit and gloves.

What is a Circuit Board?

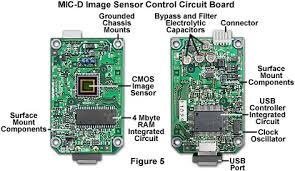

Beginning with a thin sheet of insulating material, a circuit board contains a wire “map”, usually made of copper. When an electrical charge is introduced, the wires respond by activating certain components at their point of attachment. In essence, a circuit board is an electronic traffic grid. Most commonly known as printed circuit boards (PCBs), the insulation may have one or many layers, depending on needs. These include grounding or providing heat resistance. Circuit boards are an integral part of any electronic device, no matter how large or small. If you are looking for flexible printed circuit manufacturers, look no further. At http://royalflexcircuits.com/, you’ll find just what you need.

Flex Circuit Boards Family

In the Royal Flex circuit board manufacturing process, you’ll get 30 years of experience. A reach that extends worldwide enables you to tap into a partnership that includes unprecedented engineering support from the first notion in your head through design and on to final production.

At Royal Flex, you’ll find flexible printed circuit manufacturers of the rigid-flex circuit boards. With this circuitry, your board will accommodate the entire conductor pattern of one circuit within one component. Flexible circuits are bonded to a stiffening substance through holes that have been strategically located. This provides both flexibility in one portion of the circuit with more rigidity in another.

The product line includes single- and double-sided flex circuit boards. Single-sided boards have applications for dynamic flexing or limited space and thickness. Double-sided flex boards are commonly used in digital cameras and mobile phones for example, and consist of double-sided copper clad material with top and bottom cover films. Additional options include a multi-layer flex circuit board and the combination rigid-flex circuit board.

If you need a rigid circuit board, you’ll find it here. High density circuit boards (HDI) are gaining more and more popularity due to the increased need for reduced size and weight but higher complexity. Limited space is best utilized by incorporating blind and buried vias or vias-in-pad.

What Are Blind and Buried Vias or Vias-in-Pad?

The flex circuit board manufacturing process includes vias. These are channels connecting different layers of a circuit board. A blind via connects an outer layer to an inner layer. A buried via connects inner layers but does not extend to the outside layer. Vias-in-pad simply refers to the channels or vias that are found in the insulating circuit pad.

If you’re not sure where to shop for your circuit boards, you’ll want to investigate the flexible printed circuit manufacturers at http://royalflexcircuits.com/. Let the folks at Royal Flex be your go-to source for PCBs.