A Printed Circuit Board or PCB mechanically supports electronic components that are connected electrically with the aid of the conducting paths, ETCHED trace copper foils which are laminated on a nonconductive substrate. Much of assembly, PCB design and quality control needs of the electronics industry are established by the rules set by the IPC organization. The main generic standard for the design of a printed circuit is CPI-2221, regardless of the material used to fabricate the board.

Circuit boards consisting of an insulating consisting of one or several layers of material bonded in a single entity. The additional layers serve as a grounding plate. The copper tracks are created either by setting individual lines mechanically or by coating the entire board of copper and removing the excess. To remove excess, printed circuits required are left connecting the electronic components.

Many stores of PCB can help with the design process and offer high-end features such as a router and optimizer auto trail can dramatically reduce design time. However, the best results are achieved to trace that at least some manual routing.

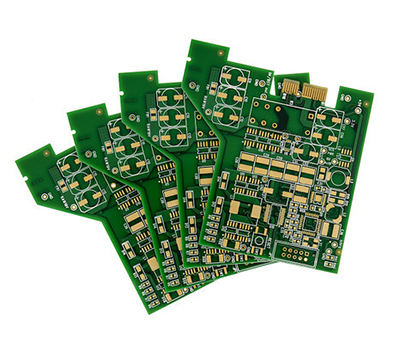

Custom PCB: There are many types of circuit boards available in variety of materials and finishes, including FR4, FR4 high temperature polyimide Getek, Arlon, alumina, ceramics, Rogers, FR1, and CEM5 CEM1. The thickness of a circuit board varies with the number of layers and can be as thin as 1.0 mm. They can be single-sided or multilayer copper clad with 1 oz or higher. While these are the PCB Standard commercially available, however, you can get a customized to suit your needs. The key is finding the right PCB manufacturer to make the boards to your specifications.

A PCB can also be used in satellites, spacecraft and other machines in outer space. Rigid copper cores are designed in a manner that conducts heat away from the sensitive parts and protect them in extreme temperatures experienced.

Some circuit boards are designed with an inner conductive layer to transfer power to various parts without having to use the more footprints. These custom needs are circuit boards that are ordered by companies to meet specific requirements with limited space. In addition, PCBs are also used by students and electronic hobbyists for their projects and custom applications. Free PCB software can easily be found online these days. It is easy to use and efficient for an amateur to a professional.

Here are some PCB’s Advantages:

1. Cost effective and highly reliable.

2. Economic for high volume production.

3. Have colour codes for different connections and are therefore easy to install.

And PCB’s Disadvantages are:

1. More design effort.

2. Higher initial cost compared to point to point circuits or wire lined built.

3. You cannot update once printed.

The information has been shared on behalf of GradConn, is offering a wide variety of custom cable assemblies, with particular strength in micro coaxial cables for wireless markets, such as GSM, GPS, Wireless LAN (WLAN), Wi-Fi and Bluetooth. Custom board to board PCB connectors are a perfect solution when you need an application specific connector.