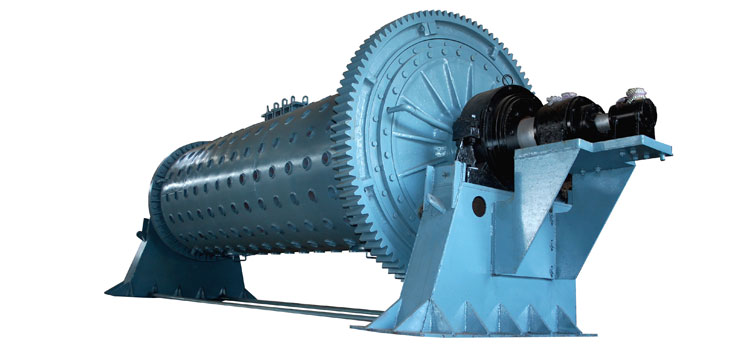

A grinder that is used to grind and blend the materials to be used in mineral dressing processes, ceramics, and paints. It works on the principle of impact and attrition. The reduction in size is done by impact as the balls falls from the top of the shell.

Generally, ball mills are being used in laboratories to process ceramic materials. This product turns the material into fine powder.

The main Properties of Grinding Media are:

- Size: The size of the final product is based on the media particles. Generally, the size of the media particles should be larger than the material to be grounded.

- Density: The density of the media should be more than the material to be grounded. It has been found problematic if the grinding media floats on the top of the material to be grounded.

- Hardness: The grinding media should be durable enough to grind the material. However, the grinding media should not be tough so that it does not wear down the tumbler at a speed.

- Composition: The variety of grinding applications have different requirements. Some requirements are on the basis of the idea that the grinding media can be the finished item. Whereas the others will be on the basis of the reaction of media with the material to be grounded.

Online you can find many ball mill manufacturers from India whom you can purchase the product as per your requirements.

Construction of Ball Mill

There is a hollow cylindrical shell that rotates on the axis. The axis of the shell is generally horizontal and is partially filled with balls. The inner portion of the shell is generally lined with an abrasion-resistant material. The example of such material is manganese steel or rubber. The length of the mill is somewhat equal to the diameter.

Applications of Ball Mill

Certain uses of Ball mill are as follows:

- Grinding material such as coal, felspar, and pigments for pottery

- Blending of explosiveness

- Increases solid state chemical re-activity

- Helps in producing amorphous materials

- Useful for both batch and continuous operation

- Useful for open and closed circuit grinding

- Used for materials of all varied hardness

- Allows you to perform wet and dry grinding

- Serves to be reliable and easy to operate

- Useful for secondary grinding

Because of the above mentioned uses, ball mill exporters select to supply the product.

Types of Ball Mills

Apart from the common ball mills, the other type of ball mills are known as planetary ball mills. These are smaller than the common ball mills and is generally used in laboratories to grind sample material into smaller sizes. Such ball mills have one grinding jar that is arranged eccentrically on the sun wheel.

The movement of the sun wheel is opposite to the grinding jar. The difference in the speed of grinding balls and jars develops the interaction between frictional and impact forces that generates high dynamic energies.