Benefits

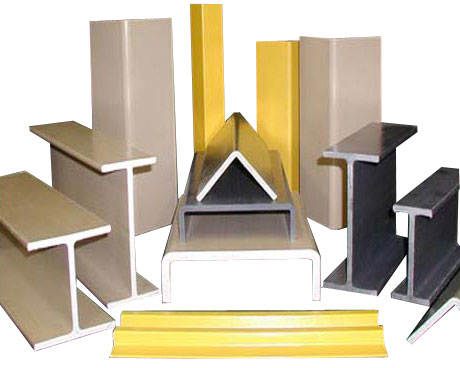

With applications across sectors such as transportation, civil engineering, construction and offshore developments, one of the biggest benefits is that the material is lightweight and yet also very strong. Typically, the sections weigh as much as 80 per cent less than steel equivalents and 30 per cent less than aluminium sections. Therefore, in projects where the weight of materials is a factor, pultruded corrugated sections have a distinct advantage without compromising on strength. Such strength makes it a sensible choice for applications for use by pedestrians, such as walkways, steps and bridges.

The addition of other resins during the manufacturing process gives the sections key benefits. Adding proprietary resins provides fire-resistant properties and has the added benefit of providing good levels of thermal stability. And yet the material is resistant to swelling, warping or stretching when tested across a range of temperatures and weights. Combinations of resin and fibre in different formulations meet the most rigorous of fire safety standards, with extremely low levels of smoke and toxicity levels should ignition occur, and crucially, shape and structural integrity are maintained at extreme temperatures.

Electrically non-conductive, the pultrusions are ideal for applications where electrical insulation is required. At the same time, adding a small degree of conductivity at manufacture allows for use in aerials and radio masts and in the medical sector, where the material’s non-magnetic property and transparency to x-rays makes it a valuable component in CAT scanning equipment.

The addition of epoxy resin makes the sections extremely durable and resistant to corrosion, even where chemicals or pollutants are present. These highly beneficial qualities make the sections extremely useful in a variety of applications, whilst the manufacturing process itself allows for sections to be cut to length with minimum waste.

Benefits On-Site

Apart from the manufacturing process and the benefits that various types of sections can offer, working with the sections on-site also has distinct advantages over other materials such as steel and aluminium. With less weight, savings can be made on transportation costs, and upon arrival at a site installation time is reduced.

The sections are easy to work with and can be cut as required using laser cut, water cut, grinder or saw; and they can be shaped via machining, drilling and punching and put together using conventional bolts and rivets, joints or bonds. The pultrusions can be integrated with numerous other materials such as masonry, wood, steel and concrete.

From an aesthetic point of view, the sections can be manufactured in any of the industry-standard RAL colours, and they are easy to clean and resistant to impacts.

Overall, due to their long life, low maintenance, cost-effectiveness and adaptability, and with an abundance of applications, corrugated sections are a wise choice in today’s demanding construction sector.