Underground mining is not a simple job at all. Safety for the job has always been a critical concern for management and employees. The miners face certain challenges in their daily activities and proper must be taken to ensure their health and safety. Irrespective of whether mining is conducted above or below ground, the mining industry presents a very volatile work environment. Under such circumstances, proper measures must be taken by the company.

With recent advancement in technology, modern equipment has been introduced and mining techniques have been made more automated. Incorporation of enhanced mining engineering has lowered the risk factor significantly. Leading mining companies have now embraced strict safety measures and established specific standards. They have also taken a proactive approach by emphasizing on worker training and education.

If you are an underground mining company, it is best to contact an equipment manufacturer for underground mining that increases safety and production. Some things you must invest on have been mentioned below:

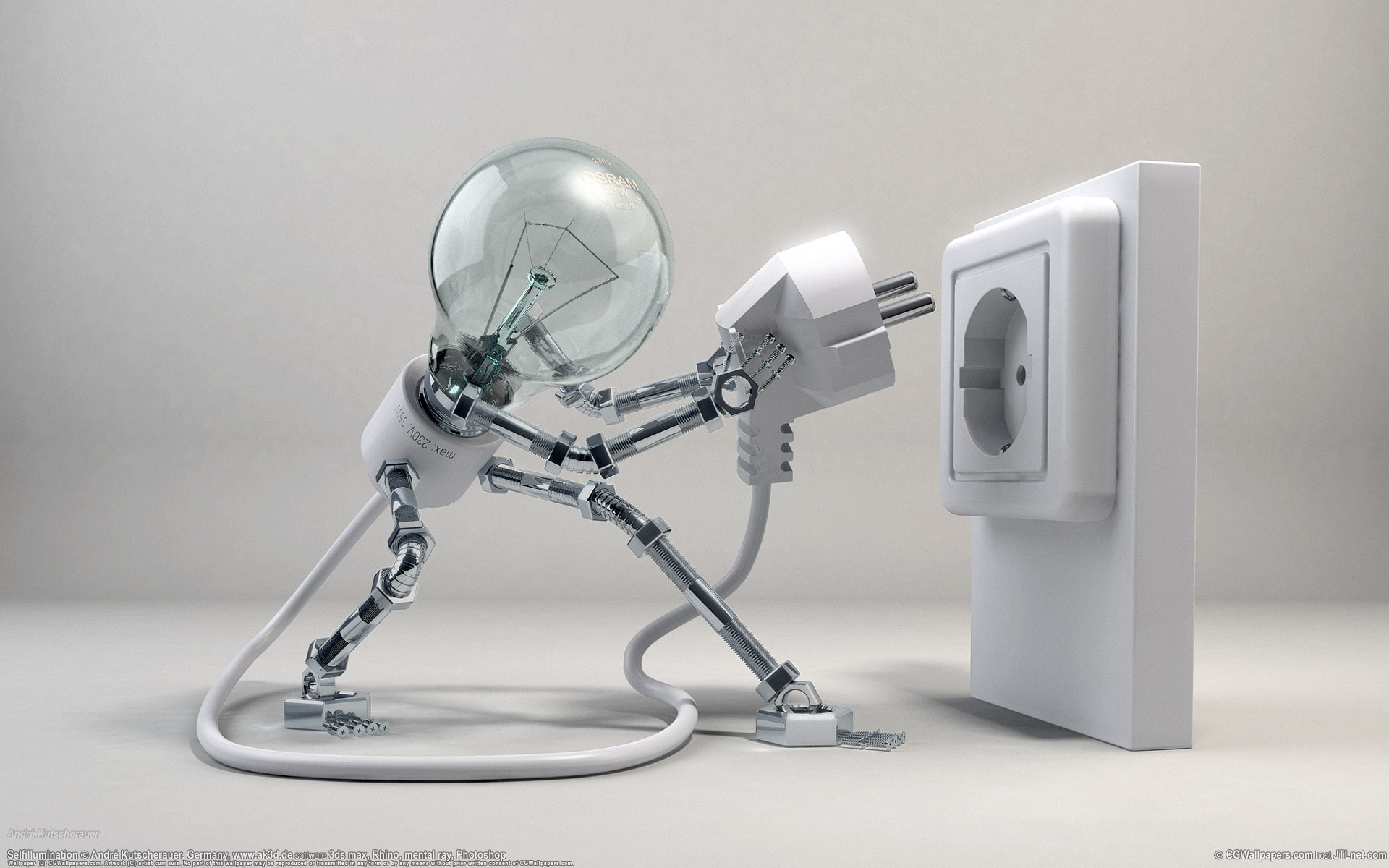

- Illumination

Minimum illumination intensity for regular tunneling operations is 5-foot candles. 10 foot-candles should be placed for shaft heading during tasks like mucking, drilling and scaling. Ensuring visibility is very important, so all lamps must be checked regularly.

- Hazard Signage

There must be proper hazard signage. All signage should be legible and highly visible.

- Communications

The underground miners often need to contact the management in a crisis situation. Therefore, telephones and all other signaling devices should be fully operational while mining operations take place. Make sure all telephones and other signaling devices are fully operational at all times.

- Ventilation and Alarm Systems

Alarms and air quality sensors will detect levels of Carbon Monoxide and other toxic vapors and gases. This system required scheduled maintenance and testing.

- Worker Identification

It is expected that mine operators will have a clear idea of every worker’s location during their shift. Entrance into the premise should be strictly monitored. One way to do this is my implementing digital Check-In Check-Out System.

- Evacuation Plans

The workplace is very uncertain and thus, disaster evacuation drills must be conducted periodically. All emergency communication and signaling devices should be checked regularly. The workers should be trained to deal with the emergency situation. Emergency gears such as breathing apparatus and HAZMAT suits must be available on site for rescue teams.

- Personal Protective Equipment

Experienced miners are taught what equipment they may need to minimize or prevent injuries during an emergency situation. Information regarding PPE and training shall be provided for newcomers. The materials used to make this equipment have improved over time.

Employees will have to adorn high-visibility jackets, flash-rated cotton coveralls or clothes with reflective stripes depending on the nature of their job. Rain gear and head gear may also be needed. Certain tasks may also require the miners to have work glove made of lightweight breathable fabric. Modern products have a better cut and are puncture resistant.

Industrial footwear must be worn by employees. Work boots for miner are higher as they help avoid ankle rollover. Choosing insulated boots can save the feet from extreme weather conditions. It is better if the sole platforms are thicker and wider as the design will provide better balance.

Led-powered hard hats are common but may miners now also choose to wear safety glasses. The new designs are fog resistant and have improved scratch abrasion.

Mine sites are prone to excessive noise due to mine blasting and sound of diesel powered machines. This can be harmful to the employee’s hearing ability. Earplugs and other protective covering can be used depending on the decibel levels in the areas.