These days, rare earth magnets are used in different applications and therefore it will be interesting to know some details about them for general understanding. These magnets are considered to be quite strong and it consists of number of different materials like iron, cobalt and nickel etc. Among them, the magnets that are made from neodymium are the strongest magnets. It can easily fit into any steel block of very less weight steel block.

Magnetic Strength

The magnetic strength of any rare earth magnet is expressed in terms of units that it can magnetize any specific alloy. In scientific term, Gauss per cubic inch is the unit of magnetic strength, which signifies how much influence the magnet has around its surroundings. In order to measure the coercivity of any magnet the term oersteds is used.

Usually, the strength of any magnet is decided by multiplying the Gauss per cubic inch with the oersteds. By multiplying these two figures, it is denoted as MGO, which stands for Mega Gauss Oesterids.

Application

As mentioned earlier, earth magnet can be used for many different applications. These days, you can very commonly find them in computer hard drives, fishing reel brakes, audio speakers, high performance AC servo motors, traction motors, wind turbine generators, permanent magnet motors and mechanically powered flashlights.

Besides that there are many other industrial applications too. In many industries, neodymium magnet is used for maintaining purity of product, equipment protection and various quality control applications.

How to Make Rare Earth Magnet

The production processes of making these magnets are quite sophisticated and delicate. It requires number of technological steps and only licensed manufacturers are allowed to produce such magnets. Following are the steps used for their manufacturing.

- Mining

All these magnets are extracted from ground through mining process, which contains plenty of iron and many other metals.

- Grinding and Mixing

After extracting the raw material they are grinded into powder form and then various other materials are mixed according to the grade requirements. Depending upon the required magnetic properties, you have to mix the amount of various other materials. With this process, you can get stronger and durable magnets that can withstand higher temperatures etc.

- Pressing

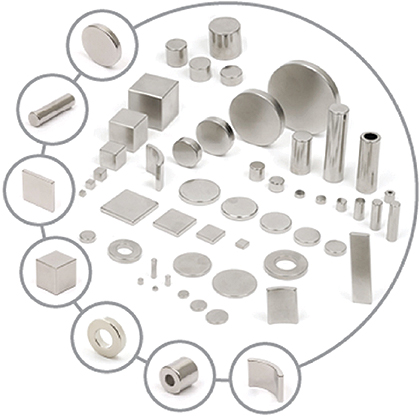

The mixtures thus created by the above process are now pressed to certain desired shape as required.

- Particle alignment

Large electromagnets are used for this process.

- Sintering

After the above process materials are sintered.

- Milling and Cutting

The materials are milled and cut to make into smaller pieces with very précised dimensions.

- Plating and coating

After the above process, the plating and coating is done so that it can be protected against corrosion. Various metals are used for coating e.g. Nickel, Copper, Epoxy, Gold or Zinc, as per required application.

- Magnetization

Finally, the finished materials are magnetized as per the required direction and they are finally inspected for various quality assurance tests.

CMS Magnetics is one of the very reputed and well known manufacturers of various kinds of neodymium magnets located at Garland at Texas. You can contact them by visiting their website for your requirement of any type of magnets.