Polymers are found in nature and are also created through chemical reactions known as polymerizations. Polymers are basically large molecules that are made up of thousands – even millions – of atoms that are bonded together in a repeating pattern. Just like a chain has many links that are connected together, the atoms within the polymer are bonded to each other to form links in the polymer chain. Synthetic polymers that are created by humans through polymerizations have several industrial, commercial and household uses. Polymer distributors and importers source such polymers from globally renowned manufacturers and brands to meet the demand for polymers in India.

This post brings to you the most common types of man-made or synthetic polymers and their uses:

Polyethylene

Polyethylene is a thermoplastic material that can be moulded into variety of shapes. It has no taste or odor, and is non-toxic, lightweight, and relatively inexpensive which makes it one of the most highly produced polymers in the world. Low Density Polyethylene (LDPE) is used for making squeeze bottles, six pack rings, electric wires, flexible pipes, toys, etc. High Density Polyethylene (LDPE) with its high tensile strength and thermal stability is used for making bottles, plastic bags, pipes, inner insulation of cables, and so on.

In India, leading polymer distributors are sourcing polyethylene in different forms – (LD/LL/MD/HD/MLLD), PE Powders – for a number of industries including Advanced Food Packaging, Advanced Technical Packaging, Automotive, Blow Moulding, Blown Films, Caps & Closures, Car Fuel Tanks, Masterbatches /Compounding, Extrusion Coating, Film, Injection Moulding, Medical, Milk, Pipe & Sheet Extrusion, Rotomolding, Textiles, and Thermoforming,

Polypropylene

Polypropylene is a rigid, thermally stable polymer with high resistance to stress, cracking, and chemical reaction. Compared to polyethylene, it is much stronger and also expensive. Polypropylene has several uses – auto parts, food containers, industrial fibers, wrapping material for textiles and food, dishware, liner in bags, etc.

In India, leading polymer importers are sourcing an outstanding range of polypropylene – homopolymers, impact / random copolymers and PP powders – to meet the diverse needs of the industry’s customer base.

Polystyrene (Thermocole)

Polystyrene is a good thermal insulator and is widely used for making petri dishes, plastic cutlery and CD case. A number of industries including Packaging, Rigid (non-foam) packaging, Rigid (foam) packaging, Food service, Other packaging, Electronics & Appliances, Construction, and Furniture rely on polystyrene supplies.

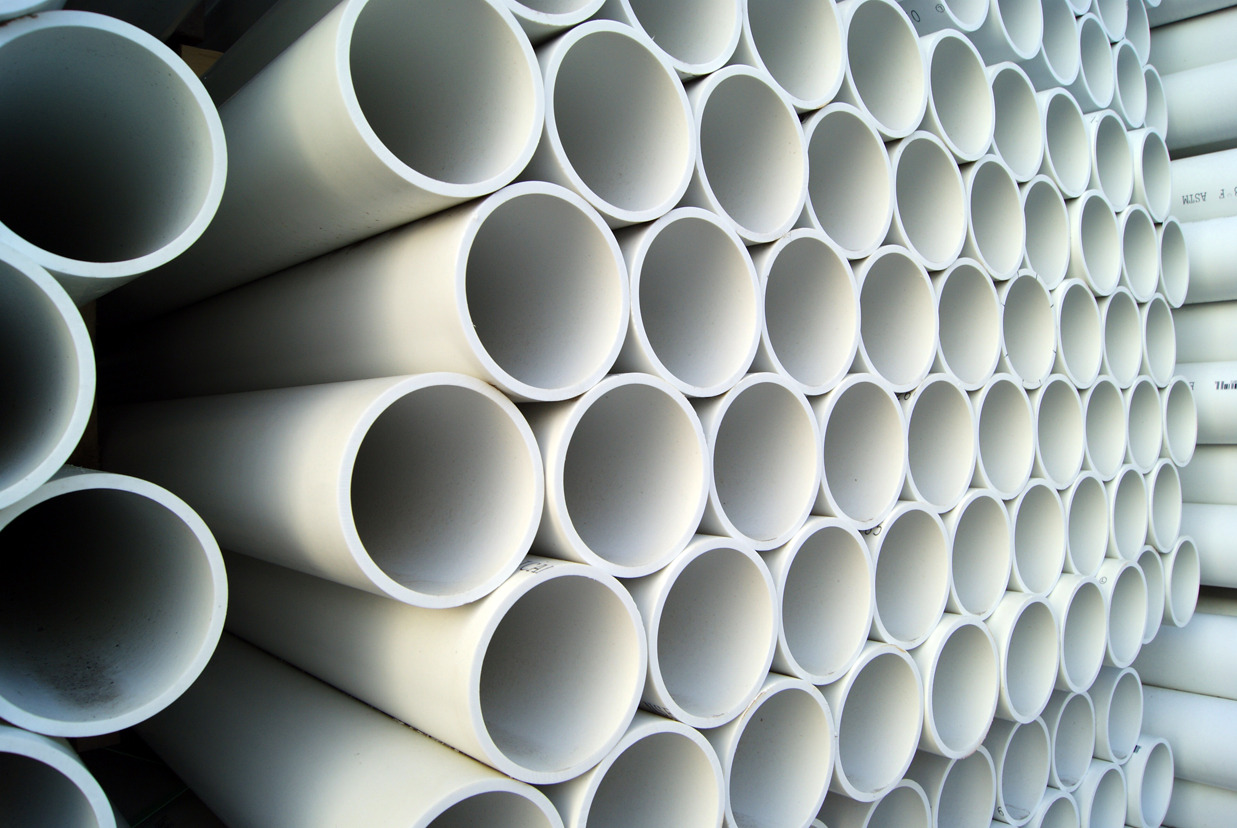

Polyvinylchloride (PVC)

PVC is more fire-resistant than polyethylene or polypropylene. The presence of chlorine substituent increases the force of attraction between polymer chains, which in turn makes this plastic extremely strong and hard. PVC is one of the most versatile plastics as its properties can be varied over a wide range by adding plasticizers, stabilizers, fillers, and dyes. It is used in draining pipes, fencing, hand bags, non-food bottles, raincoats, toys, electrical installation insulations, lawn chairs, curtain cloths, vinyl flooring, etc.

PVC is more fire-resistant than polyethylene or polypropylene. The presence of chlorine substituent increases the force of attraction between polymer chains, which in turn makes this plastic extremely strong and hard. PVC is one of the most versatile plastics as its properties can be varied over a wide range by adding plasticizers, stabilizers, fillers, and dyes. It is used in draining pipes, fencing, hand bags, non-food bottles, raincoats, toys, electrical installation insulations, lawn chairs, curtain cloths, vinyl flooring, etc.

E-PVC, S-PVC, PVC copolymers, PVC Latex, PVC compounds, PVC Matt compounds, PVC XLPE compounds and recycled compounds are some of the major categories of PVC supplies.

Polycarbonates

Polycarbonates (PC) are a group of thermoplastic polymers. The polymer units are linked through carbonate groups, including many moulding materials and films in their chemical structures. Polycarbonates are widely used in engineering owing to their strength and toughness. They can be easily moulded and thermoformed. Polycarbonate sheets of various grades are widely used in industries such as Automotive, Electronics, Tablet PCs, Mobile Devices,

Few leading India based polymer distributors and polymer importers are sourcing high quality polymers from globally renowned manufactures and brands.